How Hazelnut Defects Behave During Roasting

Roasting dramatically improves hazelnut flavor, aroma and texture — but it also magnifies the visibility and sensory impact of defective kernels. Understanding how defects behave under heat helps manufacturers optimize sorting, quality specifications and roasting parameters for consistent industrial performance.

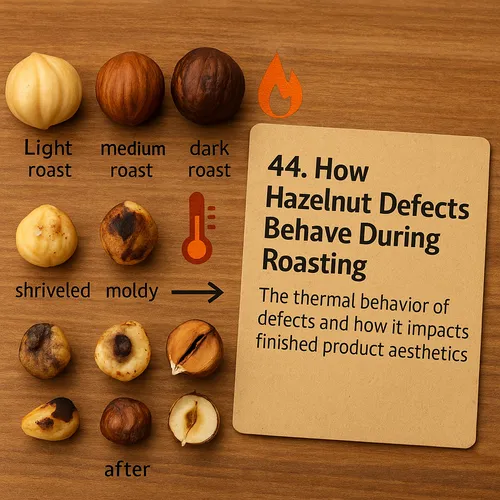

1. Why roasting amplifies hazelnut defects

Defects that are subtle in raw kernels often become dramatically more visible after roasting. Heat causes:

- Color contrast increases — dark, mold, stained or rancid kernels become more obvious.

- Texture changes — shriveled or damaged kernels may fragment or burn faster.

- Flavor intensifies — defective kernels produce bitter, smoky or off-notes.

- Structural weakness — internal defects collapse under heat, affecting inclusion quality.

As a result, strict sorting before and after roasting is standard practice in industrial chocolate, confectionery, snacking and bakery production.

2. How common hazelnut defects respond to roasting

Each defect type behaves differently when exposed to heat. Understanding these behaviors helps manufacturers adjust roasting parameters and sorting tolerances.

▶ Shrivel (undeveloped kernels)

- Roasts faster due to lower mass and higher surface-to-volume ratio.

- Often becomes over-roasted or burnt at standard temperatures.

- Results in bitter or sharp flavor notes.

- Ideal to reduce via pre-sorting or size calibration.

▶ Moldy kernels

- Heat does not neutralize mold toxins — unsafe even if visually improved.

- Produces strong, unpleasant aromas during roasting.

- Must be eliminated via optical sorting and quality control.

▶ Dark or stained kernels

- Dark areas become darker, increasing visual rejection rate.

- Common in chocolate-covered applications, where aesthetics matter.

- Not necessarily unsafe, but negatively impacts premium grades.

▶ Rancid kernels

- Roasting intensifies the off-flavor profile.

- Often produces harsh, oxidized aromas.

- Must be excluded through storage control and sensory screening.

▶ Broken or mechanically damaged kernels

- Edges roast faster and may burn quickly.

- Small fragments may be filtered out depending on the line.

- Suitable for chopping or meal production but not premium whole-kernel applications.

3. How roasting parameters affect defect visibility

Roasting conditions influence how strongly defects appear in the finished product.

Temperature

- Higher temperatures create rapid browning, exaggerating surface defects.

- Lower temperatures allow more uniform development but require longer cycles.

Time

- Extended roasting deepens color and increases contrast between good and defective kernels.

- Short cycles may mask mild defects but reduce flavor development.

Airflow & drum rotation

- Uniform heat distribution reduces localized burning of defective kernels.

- Poor airflow often worsens fragmentation of weak or shriveled kernels.

4. Sorting before & after roasting

Industrial processors use a combination of mechanical, optical and manual sorting stages to minimize defect appearance after roasting:

- Pre-roast sorting removes mold, shrivel, foreign matter and severe defect types.

- Post-roast optical sorting removes kernels that darken excessively or burn.

- Manual belt inspection remains essential for premium grades.

For chocolate manufacturers, “double sorting” (before and after roasting) is standard practice.

5. Impact on different product applications

Chocolate & confectionery

Whole-kernel inclusions require visually clean kernels. Even mild defects become visible after roasting and can be seen through coatings. Strictest quality grade applies.

Snacking & nut mixes

Aesthetic tolerance varies by retail tier. Burnt or shriveled kernels negatively impact flavor.

Chopping & slicing lines

Structural defects fragment easily, affecting yield consistency.

Meal & flour production

Mild defects have less visual impact but still affect flavor profile and oxidative stability.

Need roasted hazelnuts with strict defect tolerances?

Atlas Hazelnuts supplies calibrated, graded and roast-optimized kernels for industrial applications.