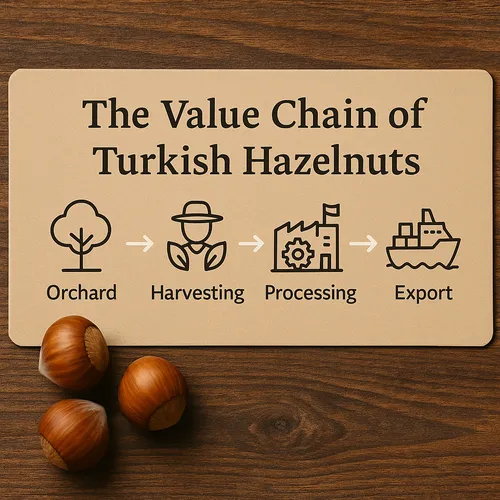

The Value Chain of Turkish Hazelnuts

Türkiye controls more than 60% of global hazelnut production, supported by a complex and highly specialized value chain. This article maps the journey from orchard to export, revealing the agricultural, economic and industrial systems that enable consistent supply for chocolate, confectionery, bakery and ingredient markets worldwide.

1. Orchard foundation: smallholder-driven production

Turkish hazelnut cultivation is built on a decentralized smallholder structure. Most orchards range between 0.5 and 5 hectares, with families managing the same groves for generations. This structure supports rural economies while ensuring a wide genetic and regional diversity of hazelnut varieties.

- Traditional hand-harvesting methods remain dominant

- Minimal chemical inputs compared to intensive crops

- Long-standing orchard knowledge passed across generations

- Regional cultivars: Tombul, Foşa, Çakıldak, Kara, Mincane and others

Türkiye’s Black Sea climate (humid, mild, stable) provides ideal growing conditions, contributing to consistent kernel quality and the globally recognized flavor profile.

2. Harvesting, drying & farm-level pre-processing

Harvest typically occurs between late July and mid-September, depending on region and elevation. Nuts are traditionally collected by hand or with mechanized blowers and nets.

Critical pre-processing steps:

- De-husking: removal of husks to expose in-shell nuts

- Sun drying: moisture reduced to ~12–14% for safe storage

- Initial defect separation: removal of empty or damaged shells

- Bagging: jute or PP bags allow moisture ventilation

Proper drying is essential; insufficient drying increases mold risk, while over-drying reduces crack-out efficiency for processors.

3. Cracking & industrial processing

Once delivered to processing facilities, hazelnuts undergo specialized mechanical sorting and calibration to prepare kernels for global ingredient markets.

Key stages in processing plants:

- Shell cracking: high-precision cracking machines separate kernels from shells

- Air & gravity separation: removes shells, husks, dust and light materials

- Optical sorting: color and defect sorting using modern vision systems

- Hand picking: manual quality control for premium-grade lots

- Calibration: sizing into 9–11, 11–13, 13–15 mm and other grades

At this stage, kernels may also be blanched, roasted, chopped, sliced, milled or pressed depending on their final application.

4. Quality control, testing & certification

Food safety and quality assurance are integrated at multiple points in the value chain. Exporters must meet strict standards for EU, U.S., Middle Eastern and Asian markets.

- Moisture testing (target 3–5% for kernels)

- Aflatoxin testing using HPLC or ELISA methods

- Microbiological analysis (TPC, yeasts, molds, pathogens)

- Defect rate measurement using calibrated visual inspection

- Traceability from orchard lot to finished export pallet

Many processors are certified under GFSI-recognized systems such as BRC or FSSC 22000.

5. Packing, warehousing & export readiness

Once processed and approved, hazelnuts are packed according to customer specifications and destination requirements.

Typical export packaging:

- Vacuum-packed 25 kg bags (most common)

- 50 kg PP sacks for certain markets

- Big bags (500–1000 kg) for industrial processors

- Cartons or palletized loads for premium products

Finished product is stored in controlled-temperature warehouses before shipment, minimizing changes in moisture and preventing oxidative degradation.

6. International shipping & export documentation

Türkiye exports hazelnuts to more than 100 countries. Exporters coordinate documentation and logistics with freight forwarders to ensure smooth customs clearance.

Common export documents:

- Commercial invoice & packing list

- Certificate of Origin

- Phytosanitary certificate

- Health certificate

- SGS or third-party inspection report (optional)

Containers are typically shipped FOB, CFR or DAP depending on buyer preference.

7. Value creation: how each stage adds economic and functional value

Every stakeholder contributes differently to the final value of the exported kernel or processed ingredient. The chain extends from orchard operations to global distribution.

- Farmers: primary production, cultivar management, drying quality

- Local collectors: aggregation of raw in-shell nuts

- Processors: cracking, cleaning, calibrating, blanching and packaging

- Exporters: compliance, documentation, international logistics

- Brands & manufacturers: application development & product innovation

Türkiye’s integrated value chain ensures steady availability, consistent quality and strong export capacity.

Need Turkish hazelnuts for industrial use?

We supply raw, blanched, roasted, chopped, milled and oil formats with full documentation and global delivery options.